Team:

Hunia Tomoum

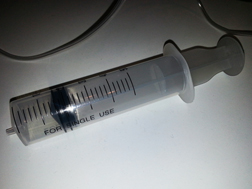

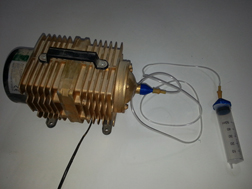

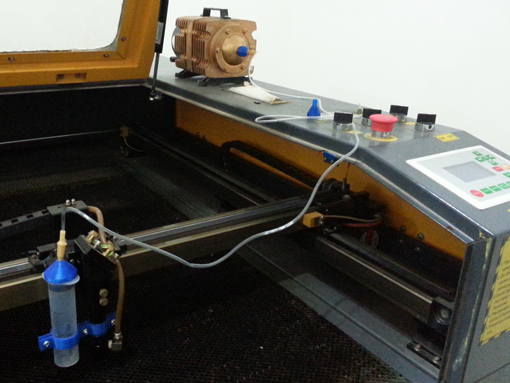

Digital deposition was done by attaching a depositing system to a laser cutter's pen. The depositing system was created using a syringe and cannula along with 3d printed parts to connect to aircompressor.

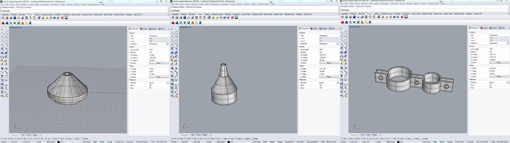

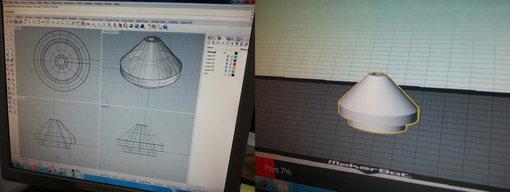

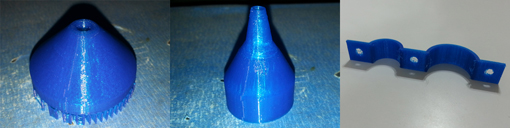

3D Printed parts

3 connections were 3D Printed. Part between compressor and canula tube rubber end. After it was modeled it was hollowed using mesh mixer to reduce of amount of PLA used. Part between canula tube rubber end and syringe. The syringe handle was removed only keeping the rubber disk. Parts connecting syringe to laser cutter pen. The parts were fixed together with screws and bolts.

Preparing the machine

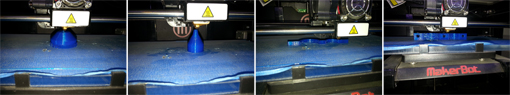

Syringe handle was removed from the syringe and 3d printed parts were fixed to syringe & air compressor. Laser cutter 's compressor was used to push rubber disk down the syringe. Basic recipe of bioplastic was then prepared. A dough gun was used as medium to fill the syringe through a clean filling process. The file drawn has to be a continuous line to avoid any arbitrary depositions resulting from laser cutter's pen movement to go from one end point to another starting point of another line. 3d Printed parts fixed to the syringe and machine, after syringe has been filled. Aluminium foil has to be covering the laser cutter's bed while fixing to avoid bioplastic leaks to lasercutter 's floor. The laser cutter's air compressor air flow was connected to the syringe, while the power was connected to the laser cutter, so as to control the deposition from the machine itself. The laser and fan buttons were turned off during the whole process.

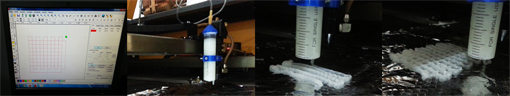

Digital deposition

Aluminium foil has to be covering the laser cutter 's bed while printing. First deposition trial did not work because the mix dried in the process of feeding bioplastic to syringe from dough gun. Second trial, the dough gun process was skipped, to keep the mix hot and therefore lower viscousity. Third trial was with the same mix of the second trial but it began to dry out, therefore higher visousity. Consequently, the output was inconsistent in the printing process.